Technically speaking, in order to find anomalies in the time series, one has to apply suited metrics, which are able to measure the distance between them and then find the time series with an increased distance from those time series, which behave normal. It is therefore necessary to transform data in a certain way, such that those metrics are applicable. Desired attributes of these transformations are that they simplify the interpretation of the data, as it is for example the case in topological data analysis methods.

Finally, it is favorably to use and analyze the data as efficiently as possible, in the sense that complex, non-linear, dependencies between the different sensors can be found and exploited. The use of multivariate probabilistic models should lead to a better understanding of the whole mechanical system and reduce redundancy. To this end, tractable probabilistic methods, like Sum-Product Networks, and methods for the exploration of non-linear dependencies, such as copulas, will be used.

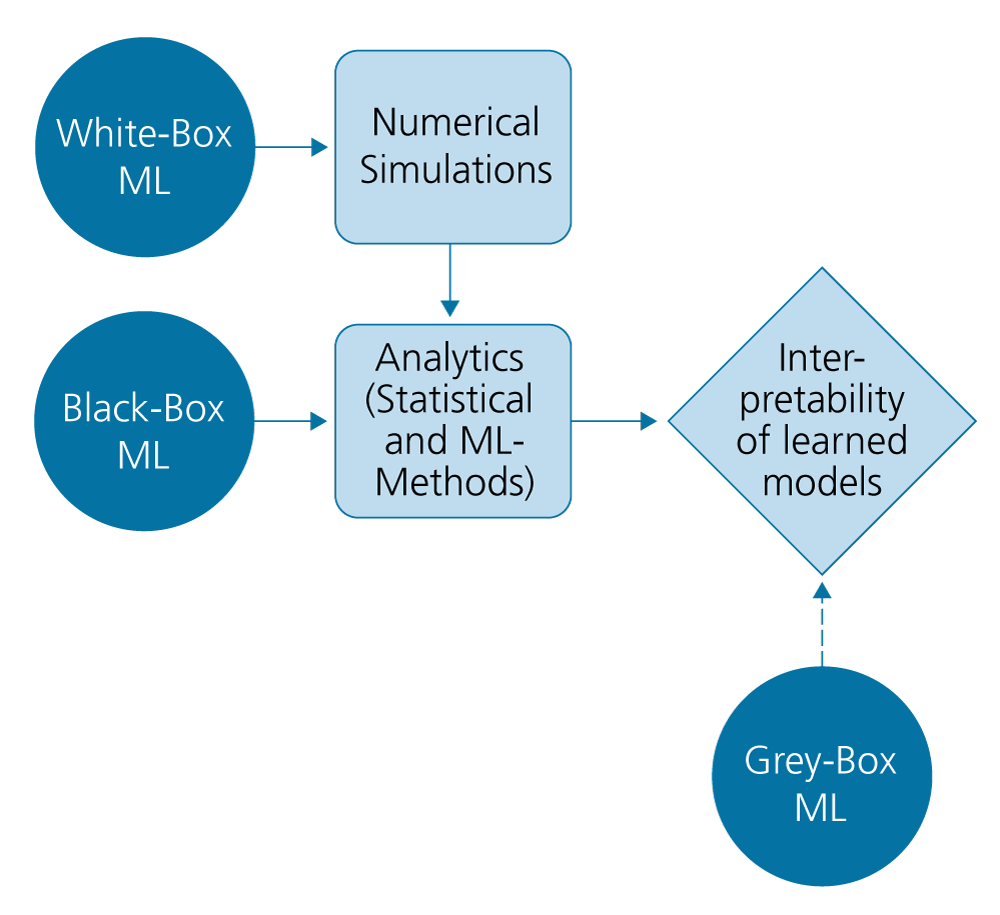

Having created a large set of simulations, these shall be stored together with real measurement data in a common data base and an interface shall be developed, which makes it possible to find targeted measurments/simulations, with a desired set of parameters and those, which are similar to them. The combination of analysis of real measurement data and controlled simulation data shall then lead to the development of so called Grey Box ML-methods.

The MADESI project is being performed in cooperation between Fraunhofer SCAI, TU Darmstadt, as well as Weidmüller Monitoring Systems and ZF Friedrichshafen.

Project duration: 10/2018 - 09/2021

Machine-Learning Techniques for stochastic-deterministic multi-sensor signals

Machine-Learning Techniques for stochastic-deterministic multi-sensor signals